What Is The Test Pressure Of P1 Class Hummed Pipes . the asme code b31.3 recommends allowable tensile stress levels in pipe materials. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. — class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. Maximum stress to be applied on a structural material; — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. The key difference between them is their ability to.

from www.araner.com

— class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. the asme code b31.3 recommends allowable tensile stress levels in pipe materials. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. The key difference between them is their ability to. Maximum stress to be applied on a structural material;

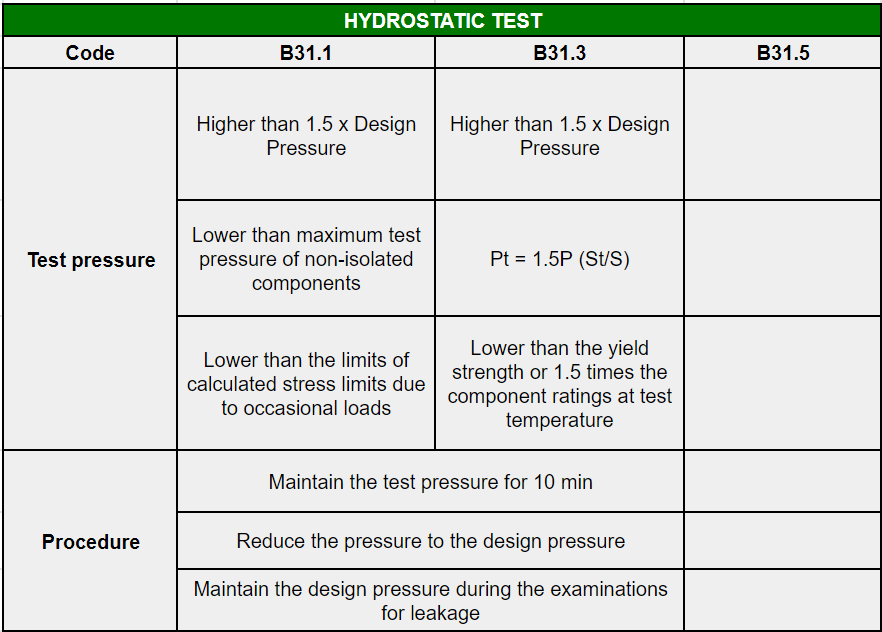

Pressure Test Hydrostatic and Pneumatic Test Requirements

What Is The Test Pressure Of P1 Class Hummed Pipes this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. The key difference between them is their ability to. Maximum stress to be applied on a structural material; design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. — class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. the asme code b31.3 recommends allowable tensile stress levels in pipe materials.

From www.chegg.com

Solved 356 The pressure difference between an oil pipe and What Is The Test Pressure Of P1 Class Hummed Pipes flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.coursehero.com

[Solved] . Water is flowing in two pipes at pressures p1 and p2. A tube What Is The Test Pressure Of P1 Class Hummed Pipes Maximum stress to be applied on a structural material; flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. the asme code b31.3 recommends allowable tensile stress levels in pipe materials. design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.acprocold.com

R134a System Pressure Chart A/C Pro® What Is The Test Pressure Of P1 Class Hummed Pipes — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. — class. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.youtube.com

Introductory Fluid Mechanics L18 p3 Minor Losses in Pipe Systems What Is The Test Pressure Of P1 Class Hummed Pipes Maximum stress to be applied on a structural material; flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. this project standard and specification specifies pressure and leak test procedure and acceptance criteria. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.toppr.com

A organ pipe P1 closed at one end vibrating in its first harmonic and What Is The Test Pressure Of P1 Class Hummed Pipes — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. the asme code b31.3 recommends allowable tensile stress levels in pipe materials. The key difference between them is their ability to. this. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.youtube.com

What We Do Pressure Testing Piping YouTube What Is The Test Pressure Of P1 Class Hummed Pipes The key difference between them is their ability to. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. — class a and class b pipes are labels that describe how much pressure. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.pvcfittingsonline.com

How Strong is PVC Pipe? (With PVC Strength Charts) What Is The Test Pressure Of P1 Class Hummed Pipes design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. — class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic.. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.pipajaya.com

hdpe pipe pressure rating chart Pipe hdpe What Is The Test Pressure Of P1 Class Hummed Pipes The key difference between them is their ability to. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. Maximum stress to be applied on a structural material; this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. —. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.united-steel.com

ASTM A335 Pipe and Featured Grades P11, P22, P91 Pipes What Is The Test Pressure Of P1 Class Hummed Pipes — class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. The key difference between them is their ability to. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. — determine the suitable pressure testing method. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.toppr.com

Water moves through a constricted pipe in steady, ideal flow. At the What Is The Test Pressure Of P1 Class Hummed Pipes flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. Maximum stress to be applied on a structural material; the asme code b31.3 recommends allowable tensile stress levels in pipe materials. The key. What Is The Test Pressure Of P1 Class Hummed Pipes.

From valveman.com

What are the Different ANSI Classes for Valves? What Is The Test Pressure Of P1 Class Hummed Pipes — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. — class a and class b pipes are labels that describe how much pressure and heat a pipe can. What Is The Test Pressure Of P1 Class Hummed Pipes.

From stainlessandalloy.com

Stainless Steel Pipe Bursting Pressure What Is The Test Pressure Of P1 Class Hummed Pipes this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. the asme code b31.3 recommends allowable tensile stress levels in pipe materials. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. — determine the suitable pressure testing. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.scribd.com

ASME B31 Standards of Pressure Piping PDF What Is The Test Pressure Of P1 Class Hummed Pipes flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. The key difference between them is their ability to. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform minimum quality. Maximum stress to be applied on a structural material; —. What Is The Test Pressure Of P1 Class Hummed Pipes.

From dxoifovzm.blob.core.windows.net

Pvc Pipe Pressure Rating Australia at Bertram Halfacre blog What Is The Test Pressure Of P1 Class Hummed Pipes design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. — class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field.. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.chegg.com

Solved Consider the system shown below. The pressure at p1 What Is The Test Pressure Of P1 Class Hummed Pipes design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. the asme code b31.3 recommends allowable tensile stress levels in pipe materials. flexpipe recommends that new pipelines that have. What Is The Test Pressure Of P1 Class Hummed Pipes.

From projectmanagement123.com

Hydrostatic Pressure Testing of Spherical Pressure Vessels Method What Is The Test Pressure Of P1 Class Hummed Pipes The key difference between them is their ability to. — determine the suitable pressure testing method based on the system or component’s characteristics, choosing between hydrostatic. design pressure shall be at least 2.0 times the specified test pressure for the section of pipe containing the bulkhead. Maximum stress to be applied on a structural material; — class. What Is The Test Pressure Of P1 Class Hummed Pipes.

From www.researchgate.net

Flow along a narrowing pipe. P1 and v1 (P2 and v2) indicate the What Is The Test Pressure Of P1 Class Hummed Pipes the asme code b31.3 recommends allowable tensile stress levels in pipe materials. Maximum stress to be applied on a structural material; flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. this project standard and specification specifies pressure and leak test procedure and acceptance criteria of piping works to perform. What Is The Test Pressure Of P1 Class Hummed Pipes.

From wiredatavyklubuhx.z22.web.core.windows.net

Schedule 80 Seamless Pipe Pressure Rating What Is The Test Pressure Of P1 Class Hummed Pipes — class a and class b pipes are labels that describe how much pressure and heat a pipe can handle. flexpipe recommends that new pipelines that have not been commissioned into operation be subjected to a field. The key difference between them is their ability to. this project standard and specification specifies pressure and leak test procedure. What Is The Test Pressure Of P1 Class Hummed Pipes.